Silage is a vital feed resource in dairy and beef operations worldwide. Properly made and stored silage can help farmers maintain a consistent, high-quality feed supply throughout the year—especially during dry seasons or periods of limited forage availability. One of the most commonly asked questions is how long silage should ferment before it can be safely and effectively fed to livestock. Below is a well-researched overview of silage fermentation times, factors that influence its readiness, and best practices for usage.

1. What Is Silage?

Silage is preserved forage (such as corn, sorghum, napier grass, alfalfa, or other crops) that has undergone fermentation in an anaerobic (oxygen-free) environment. This process preserves the nutritional value of the forage and inhibits spoilage microorganisms.

Key Benefits of Silage:

- Stable, year-round feed: Provides a reliable supply of forage when fresh grass is unavailable.

- High nutritional value: If done correctly, silage retains most of the nutrients.

- Reduced waste: Anaerobic fermentation helps prevent spoilage if storage is well managed.

2. Fermentation Time: How Many Days Until Silage Is Ready?

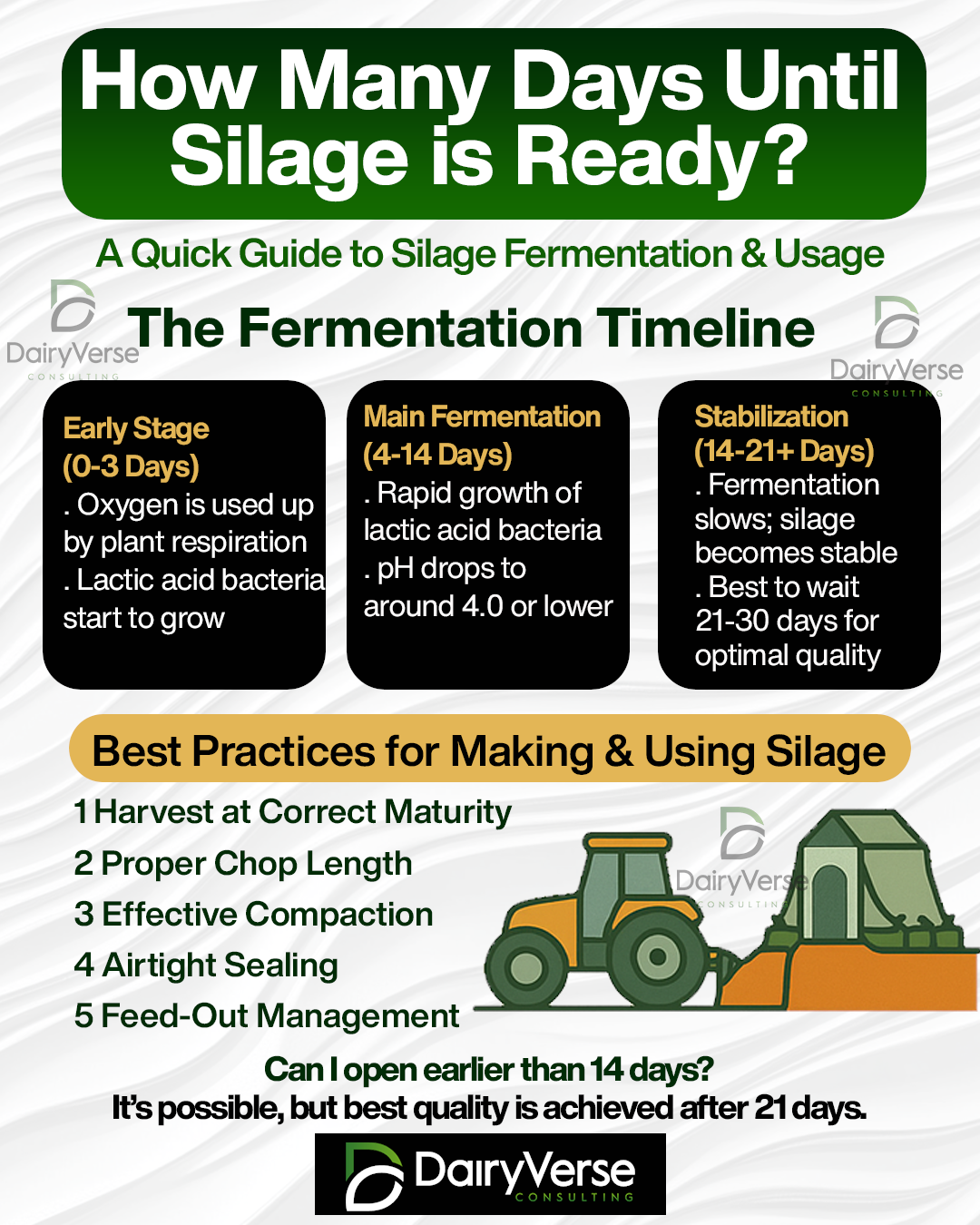

General Fermentation Timeline

- Early Stage (0–3 days): After ensiling (filling and sealing the silo or bag), oxygen is gradually consumed by plant respiration. This phase sets the stage for lactic acid-producing bacteria to thrive.

- Main Fermentation (4–14 days): Beneficial lactic acid bacteria multiply and produce lactic acid, lowering the pH. A pH of around 4.0 or lower is typically desired, as it inhibits harmful microbes.

- Stabilization (14–21 days and beyond): By around 14 to 21 days, silage reaches a stable low pH, indicating that the fermentation process is largely complete. Some sources recommend waiting at least 3–4 weeks for the best results.

Rule of Thumb: Most farmers wait a minimum of 14 days before opening their silage, but 21–30 days of sealed fermentation is often considered ideal to ensure stable pH and maximum nutrient preservation.

Why the Variation in Days?

- Type of Crop: Different crops (e.g., maize vs. napier grass vs. legumes) have varying sugar contents and moisture levels, affecting how fast lactic acid bacteria can ferment the material.

- Moisture Content: Ideal moisture for ensiling is generally around 60–70%. Excess moisture can lead to clostridial fermentation, while very dry forage may not ferment properly.

- Compaction and Sealing Quality: Good compaction (removing air pockets) and airtight sealing speed up proper fermentation and prevent spoilage.

- Ambient Temperature: Warmer temperatures generally speed up fermentation, while colder conditions slow it down.

3. Using Silage After Opening

Even after the recommended fermentation time has passed, proper usage techniques are critical to maintain silage quality.

- Feed-Out Rate:

- Once the silo, bunker, or bag is opened, you should remove silage from the “face” at a rate that minimizes the time it’s exposed to air.

- A feed-out rate of 10–15 cm (4–6 inches) per day across the entire face is often suggested for bunkers or trenches to avoid spoilage on the surface.

- Minimize Exposure to Air:

- Reseal or cover the exposed area daily if possible.

- Ensure that the silage face remains tight and well-trimmed to reduce air infiltration.

- Monitoring Quality:

- Check for signs of mold, yeast growth, or off-odors (e.g., rancid or butyric smells).

- If parts of the silage are visibly moldy or foul-smelling, discard them to prevent animal health issues.

4. Best Practices for High-Quality Silage

- Harvest at the Right Maturity:

- For maize (corn) silage, aim for 30–35% dry matter (milk to dough stage in the kernel).

- For grasses, harvest before the plant becomes too fibrous (ideally in the early boot stage).

- Chop Length:

- Proper chop length (around 1–2 cm for grass silage, 1–2.5 cm for maize silage) helps compaction and ensures good fermentation.

- Compaction:

- Use adequate weight (e.g., tractors) to press out as much air as possible when filling the silo or bunker.

- Use of Silage Additives:

- Inoculants containing lactic acid bacteria can help achieve faster and more stable fermentation.

- Enzymes or other additives can improve fermentation under certain conditions.

- Proper Sealing:

- Use plastic sheets or specialized silage covers to create an airtight environment.

- Weigh down covers with tires, sandbags, or other materials to prevent air from seeping in.

- Regular Inspection:

- Check your silage store frequently for damage, tears in the cover, or rodent activity.

5. Frequently Asked Questions (FAQ)

- Can silage be used earlier than 14 days?

- While some farmers may open silage as early as 14 days, the silage might not have fully stabilized. Nutrient quality and palatability improve if you wait at least 21 days.

- How long can silage last once opened?

- If well-managed and kept airtight except at the daily feed-out face, silage can remain good for several weeks to months. However, the key is maintaining a fast enough feed-out rate and resealing to prevent spoilage.

- Does the type of crop significantly change fermentation time?

- Yes. High-sugar crops like corn often ferment more quickly and reliably, whereas crops with lower sugar content (e.g., some grasses or legumes) may require more careful management and possibly additives.

- What if the silage has a foul smell when I open it?

- A strong butyric or rancid smell indicates poor fermentation (often due to high moisture or contamination). It’s best to discard moldy or foul-smelling portions to avoid health issues in livestock.

- Should I add water if my forage is too dry?

- In some cases, farmers lightly spray water or add molasses to help with compaction and improve fermentation. However, it’s better to harvest at the correct moisture level whenever possible.

6. Conclusion

The ideal timeframe to begin using silage is typically 2–4 weeks after ensiling, with 3 weeks (21 days) often cited as a reliable minimum to ensure proper fermentation and nutrient retention. However, factors such as crop type, moisture content, ambient temperature, and compaction quality can influence the exact number of days required. Once opened, proper feed-out management is essential to prevent secondary spoilage and maintain the silage’s nutritional quality. By adhering to best practices—correct harvesting stage, good chop length, firm compaction, airtight sealing, and careful daily usage—you can maximize both the quality and longevity of your silage.